Hollow rotating platform is an innovative mechanical device that combines high precision, high rigidity, high efficiency, strong load-bearing capacity, and smooth power transmission. It combines the advantages of servo motors, cam dividers, and drive motors and is widely used in various industries. This article will introduce the composition of the hollow rotating platform device and its high-precision implementation method.

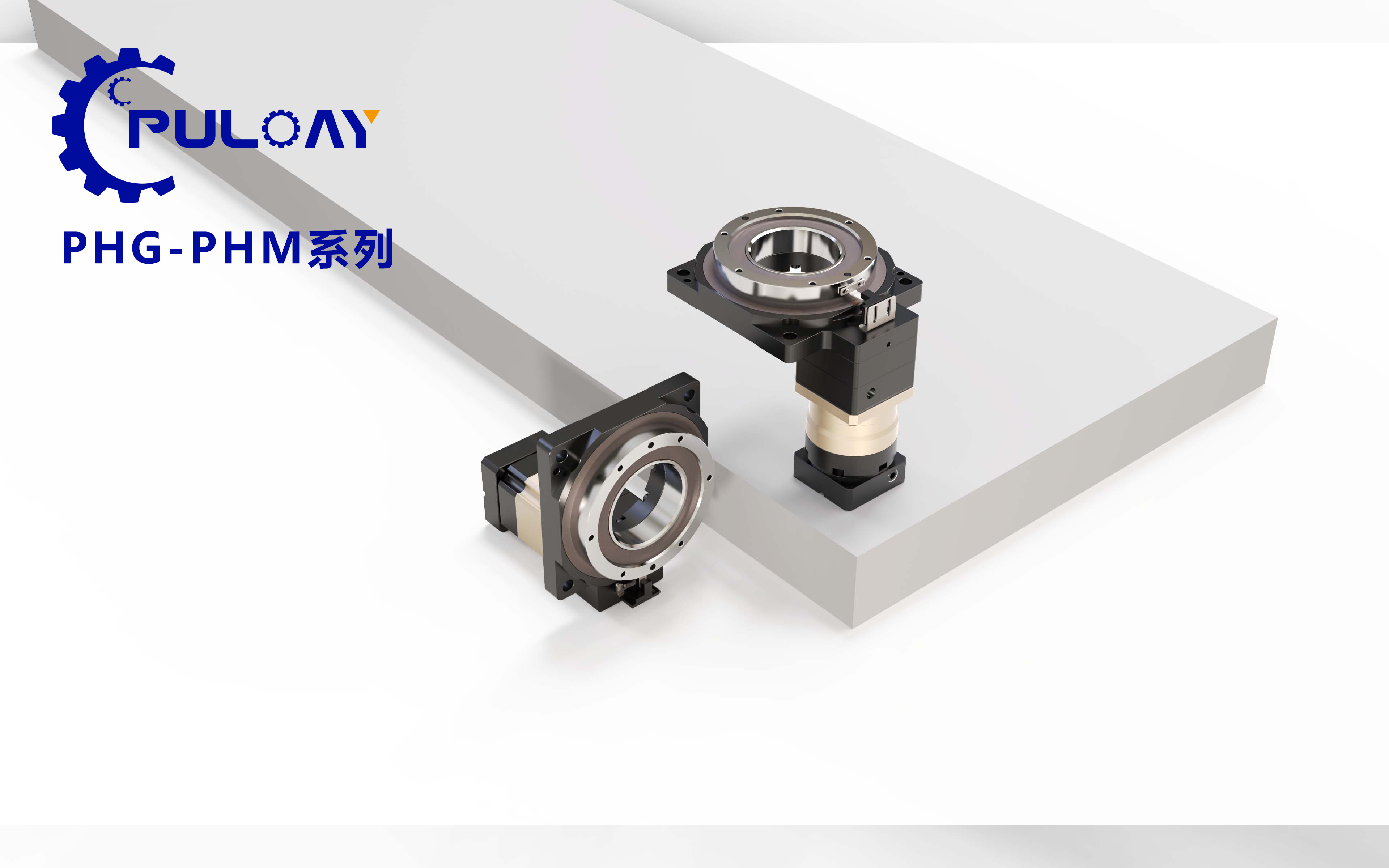

The high rigidity hollow rotating platform embeds the transmission structure into the hollow structure to achieve transmission and rotation functions. It has a hollow result design, which can achieve multi axis motion and flexible working environment. The hollow rotating platform is often composed of motors, bearings, transmission gears, etc., and precise control of motion is achieved through a precise control system. Its characteristic is that it can achieve multi axis motion through rotation, fully utilize space, and improve the flexibility and efficiency of equipment.

The gears in the hollow rotating platform are mainly divided into external gears and internal gears. The external gears are fixed on the rotating platform, while the internal gears are connected to the main shaft. The number of teeth and meshing angle of the gears determine the required rotational reliability and accuracy of the rotating platform. The manufacturing accuracy of the gears directly affects the accuracy of the rotating platform. In the manufacturing process, it is necessary to strengthen the control of gear processing and grinding technology, reduce the tolerance range, and ensure the meshing accuracy and transmission efficiency of the gears.

If the gear design of the servo hollow rotating platform is unreasonable or the two wheels do not match, resulting in the gear meshing accuracy and motion accuracy not meeting the requirements, only precise gear design can reduce this problem. If the heat treatment process is not good, the hardness is not enough, or no heat treatment is carried out, the gear hardness can be improved by carburizing and quenching. Poor forging process may result in defects such as air holes, sand holes, loose holes, and insufficient ball ink, which are very important to the gear. If the material of the forged gear does not meet the design requirements and causes abnormal wear, high-strength, wear-resistant, and high toughness gear manufacturing should be used.

The integrated hollow rotating platform is widely used in medical equipment, packaging machinery, aerospace and other fields. In medical equipment, the hollow rotating platform is used for rotation control of imaging diagnostic equipment. In packaging machinery, the hollow rotating platform can be used for object rotation positioning and packaging. In the aerospace field, the hollow rotating platform is used for attitude and positioning control of spacecraft. It has a wide range of applications in the industrial field. The rotating platform is commonly used in automation systems, robots, laser processing equipment and other fields. In automation systems, the precision hollow rotating platform can be used as a turntable for automated wiring to achieve component positioning and transmission. In the robotics field, the hollow rotating platform can achieve multi axis operation of the robotic arm, improve the functionality and flexibility of the robot. In laser processing equipment, The hollow rotating platform can achieve precise positioning and rotational machining of workpieces, improving machining accuracy and efficiency.

If you want to learn more about hollow rotating platforms, you can follow the industry news section on the official website of ProWay Transmission Technology. If you need detailed information on the selection of hollow rotating platforms and 3D dimension drawings of reducers, please call us. We have professional technical engineers to provide selection services for you. Contact number: 13825717210, dedicated to serving you